how does a brushless rc motor work

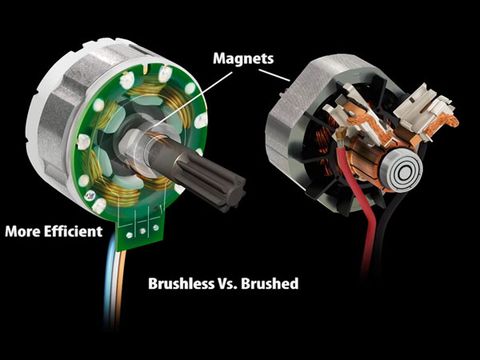

Its cut into multiple sections. Brushless motors however use electrical means of commutation.

The Brushed Dc Motor Still A Very Viable Option Part 1 Operation Electrical Engineering News And Products

Resulting in a longer run time and often less heat generation.

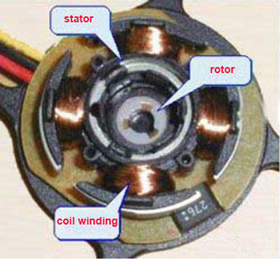

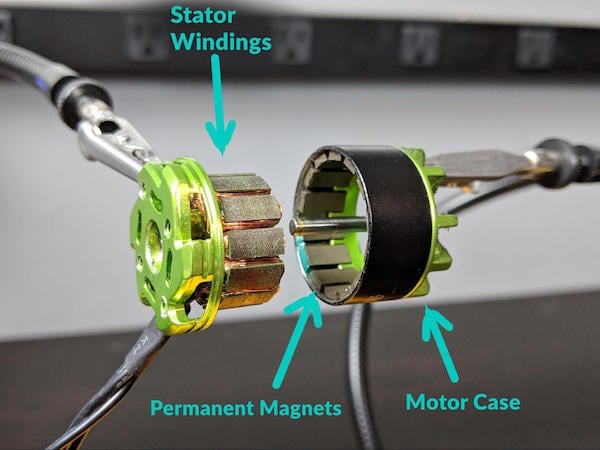

. Post 6925024 - RC Universe discussion forums for RC cars rc trucks rc airplanes rc helis rc boats rc jets rc electric helis rc electric planes and more RCU Forums - View Single Post - How does a brushless motor work. The permanent magnets that would wrap around the armature in a normal motor are instead placed around the motor shaft and this assembly is called the rotor. Sensored vs Sensorless Brushless Motor Applications This brushless motor is ideal to be used in RC cars planes drones and other small DIY projects.

Speed of the motor is the torque avaiable or current response of the drive unit. It also makes use of an amplifier that is triggered by an electronic device such as an optical encoder to create a magnetic field inside the motor. The brushes eventually wear out.

On a brushless DC motor it is not the motor shaft that rotates but rather. Theyre powered by a supply of DC energy from a battery pack that provides juice to the system until its exhausted. The difference is with a permanent magnet rotor you must accurately commutate the power since the fields are so strong.

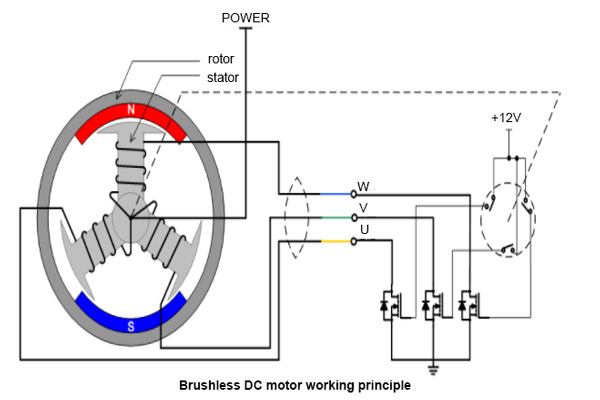

Higher top speeds. They require a control that decides when to switch the direction of current in the wires based on the relative position of the magnets and the wires. They are smaller in size thereby.

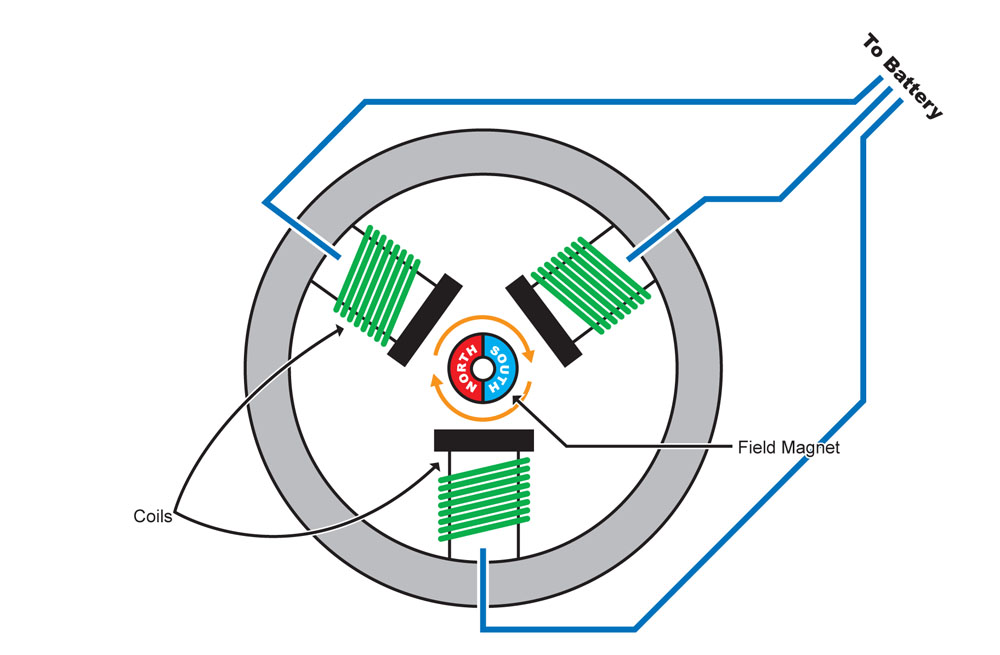

Instead of using brushes and a commutator the motors use a step motor controller. Traxxas Rustler RTR XL-5 RC Car 3. The ESC switches current between the wires that creates push and pull and makes the rotor spin.

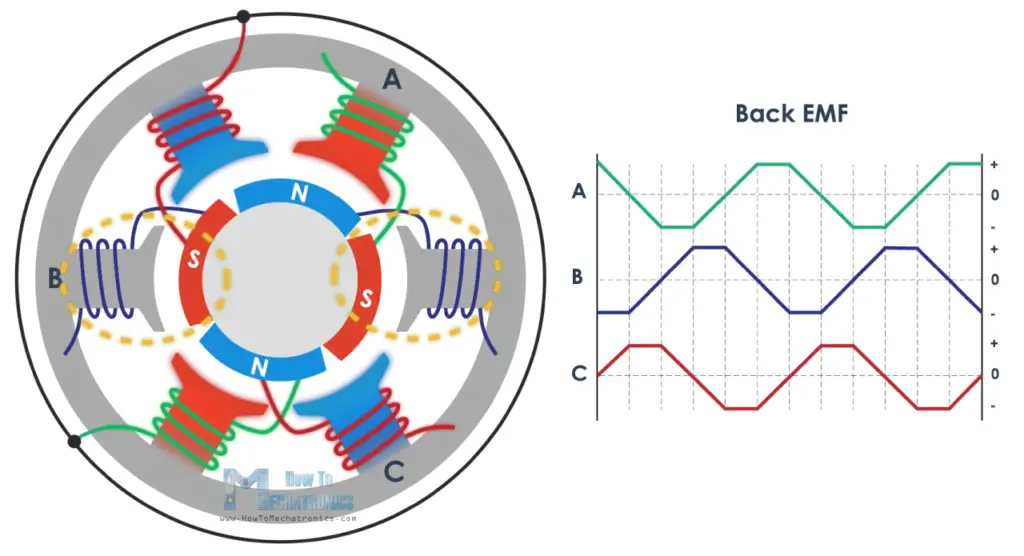

Sometimes this is just called a brushless control but in the RC world this is called an brushless ESC electronic speed control. Brushless motors are synchronous electric motors that move around electronically. One of the ways this can be achieved is through using the back-EMF of the motor to actively monitor the rotor position and therefore speed.

In a brushless generator the motor does not rotate. The transistors swithc the field in a rotary fashion just like 3 phase power does in an industrial AC motor. Beyond checking the bearings brushless motors require minimal maintenance there are no brushes to wear out.

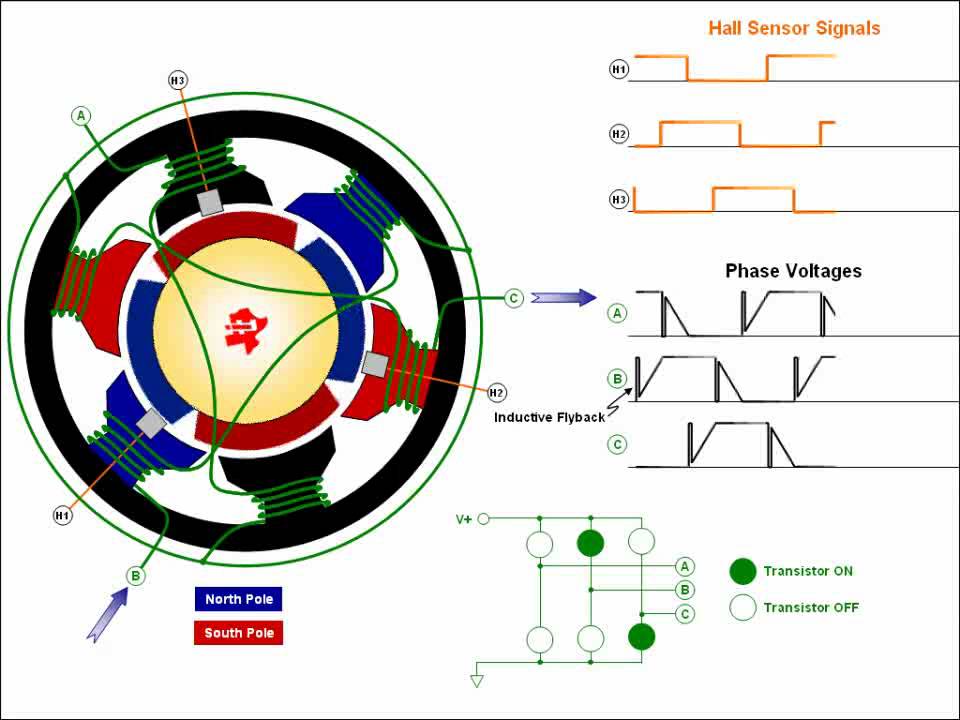

At any point of time one wire is powered one is grounded and one works as the sensor. The Kv rating not to be confused with kilo-volt is the RPM of the motor k per volt V with no load. Brushless ESCs need information on the current position of the rotor to be able to start the motor and choose a direction for the rotation.

In addition to the external rotor a brushless rc motor uses three phases of the drive coil and an additional sensing device. They utilize direct current powering magnets to move the rotor within the stator. To determine its position the ESC uses information from the last unpowered electromagnet to measure its induction.

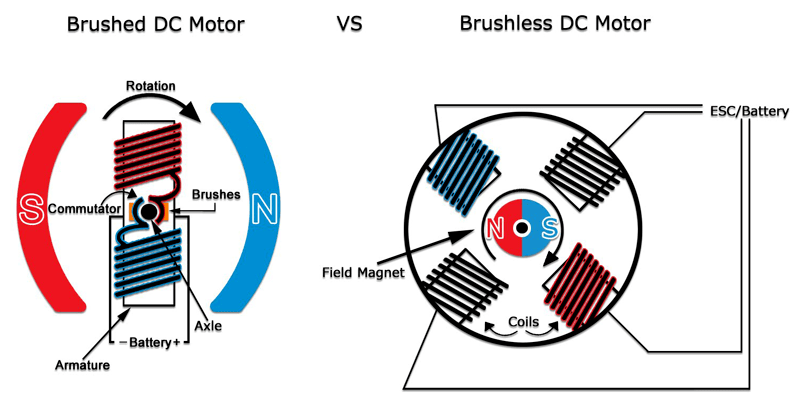

The life of the brushless motor is 2-3 times longer than brushed motor and the power consumption is only 13 of the brushed. Based on the fact that the motor has no in built sensors then this means that the brushless motor controller has to operate the motor without the use of sensors. This setup works and is simple and cheap to manufacture but it has a lot of problems.

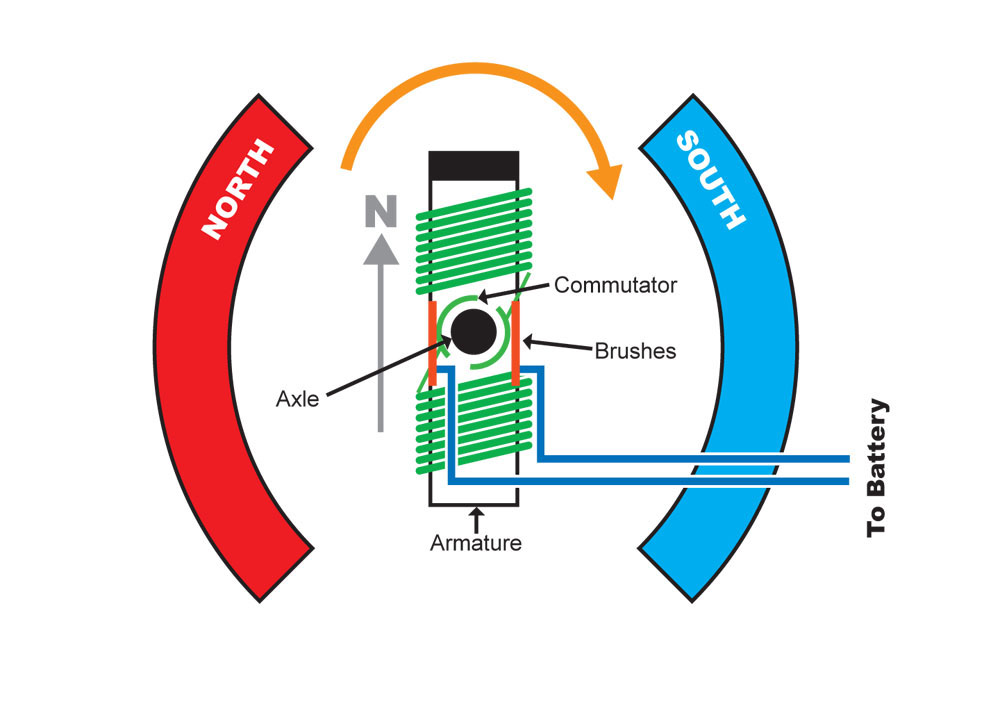

Because the brushes are makingbreaking connections you get sparking and electrical noi. Brushless motor advantages. They make contact with two spinning electrodes attached to the armature and flip the magnetic polarity of the electromagnet as it spins.

According to this signal the controller the ESC drives the brushless motor appropriately. The difference between the speed of the rotating magnetic field and the rotor speed. An electronically commutated motor assembly better known as a brushless DC motor is a basic part of the world of modern RC cars.

More load more slip. This brushless motor is ideal to be used in RC cars planes drones and other small DIY projects. Your RC Car manual should give recommendations on gear ratios.

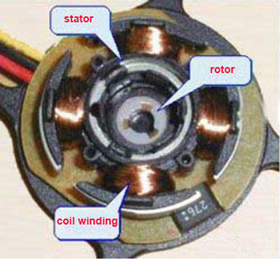

These magnets that we have talked about make the electric current pass directly through the winding of the housing or the stator creating an electro magnetic field that together with the magnetic field of the magnets generates an intrinsic force that makes the rotor rotate and consequently the motor shaft does as well. Thanks to the reduced friction and efficient torque delivery with a wider speed range. The basic explanation of a brushless motors construction is that it is similar to a brushed motor except everything is inside out and there are no brushes at all.

Lack of brushes can significantly broaden the maintenance intervals thereby the maintenance cost of the RC car. The windings are glued to the inside of the can and the permanent magnets are bonded to the rotor. A brushless motor is inside out compared to your GWS motor.

How does a brushless motor work. Like brushed DC motors brushless motors work by alternating the polarity of the windings on the interior of the motor. An ESC or an Electronic Speed Controller controls the brushless motor movement or speed by activating the appropriate MOSFETs to create the rotating magnetic field so that the motor rotates.

The magnetic fields created when the coils are generated exert a pushpull force on the permanent magnets arranged around the outside of the casing. We just finished developing our first prototype for a brushless DC motor and Tomas is here to explain how it all workssubscribe. 10 Best RC Drift Cars When it.

Take a look at the commutator on the GWS motor. Since the wires dont move you dont need brushes to transfer the electricity. Can brushless motors work without ESC.

Efficiency and power to weight ratio are high comparativelyIt interprets to a higher acceleration and easy overtakes. An RC brushless motor consists of some three-wire coils that create electromagnetic forces. Besides the external rotor a brushless motor uses three phases of driving coil and an additional sensor device to sense the position of the rotor and the drive electronics.

The higher the frequency or the quicker the ESC goes through the 6 intervals the higher the speed of the motor will be. In the brushless the motor is inside-out with the field as the rotor and the windings as the stator. This is the max RPMs that this motor can reach under no load.

The ability of the drive unit to keep up with the demand frequency ie. For example a brushless motor with a Kv rating of 3000 powered by a 12V power source would be capable of 36000 RPMs multiply 3000x12.

Motor Control Solutions Brushless Dc Vs Pmsm Motor Controller

The Brushed Dc Motor Still A Very Viable Option Part 1 Operation Electrical Engineering News And Products

How A Brushless Dc Motor Works Custom Maker Pro

What Is Brushless Dc Motors Bldc Utmel

Futurelab3d How Brushless Motor And Esc Work

Electronics Idea How Brushless Motor And Esc Work

Drone Motor Fundamentals How Brushless Motor Works Drone Nodes

How A Brushless Motor Works Animation Youtube

Brushless Vs Brushed Dc Motors When And Why To Choose One Over The Other Article Mps

Brushless Vs Brushed Motor What S The Difference

Brushless Dc Motor How It Works Ato Com

What Is A Brushless Motor And How It Works Torque Hall Effect 3d Animation Youtube

Futurelab3d How Brushless Motor And Esc Work

Brushless Vs Brushed Dc Motors When And Why To Choose One Over The Other Article Mps

Brushless Vs Brushed Dc Motors When And Why To Choose One Over The Other Article Mps

What Is A Brushless Motor Answered Tyto Robotics

Brushless Dc Motor How It Works Ato Com